By Peter Joslin

Finishing & Distribution Manager/Lane Press

Should we perfect bind or saddle stitch our book?

I hear this question from customers quite often—and it’s an important decision, because the choice impacts the overall quality of a magazine as well as readers’ impression of it.

As the finishing-and-distribution manager at Lane, one of my responsibilities is to monitor the quality of the magazines we produce. First and foremost, I inspect books from a manufacturing standpoint: Are they square? Is the trim accurate? Is the bleed right? But as someone who holds a master’s degree in fine arts, I’m also keenly interested in the design and look and feel, all of which helps make a magazine unique. Having looked at literally millions of magazines, I believe binding style is a choice that dramatically affects the design and, ultimately, the reading experience of a magazine.

As the finishing-and-distribution manager at Lane, one of my responsibilities is to monitor the quality of the magazines we produce. First and foremost, I inspect books from a manufacturing standpoint: Are they square? Is the trim accurate? Is the bleed right? But as someone who holds a master’s degree in fine arts, I’m also keenly interested in the design and look and feel, all of which helps make a magazine unique. Having looked at literally millions of magazines, I believe binding style is a choice that dramatically affects the design and, ultimately, the reading experience of a magazine.

Sometimes the choice is easy: From a purely mechanical standpoint, a magazine that’s too thin cannot be perfect bound, and a magazine that’s too thick can’t be stitched. Most magazines fall somewhere in between, though, and that’s when the choice is less clear-cut.

Specifically, a magazine that runs between 48 to 116 pages may be either perfect bound or stitched. Just because you can, though, doesn’t mean you should. By that I mean there is a set of magazine characteristics that beg for perfect binding. In these scenarios, a magazine is actually enhanced by that binding style. Absent those circumstances, perfect binding may feel forced and actually detract from the overall impression of your magazine. The same goes for saddle stitching.

Here are some considerations to ensure your binding contributes to the style and function of your magazine:

Perfect Binding

Spine Size. Generally speaking, perfect binding offers a tight, book-like feel that is best achieved with a substantial spine. Spine size is determined by page count, paper basis weight, and a bit of adhesive. To achieve a quality perfect binding, your magazine’s spine should be at least an eighth of an inch. Anything thinner and you start to lose that book-like feel—and, during the manufacturing process, it becomes difficult to keep the spine square and the spine copy centered.

Rule of thumb: The minimum page count to achieve a 1/8” spine is 48 pages, assuming a text and cover basis weight of 70# to 80#.

Paper Basis Weight. The basis weight of a magazine’s paper stock also helps determine its heft and substance. The lower the basis weight, the more pliable and even flimsy a perfect bound magazine feels in your hands. Magazines printed on a higher basis weight paper will seem more firm and substantial.

I also encourage magazine publishers to think carefully about the cover stock in terms of how it will function on a perfect bound magazine. Ideally, the cover should open and fold back with ease but also a bit of resistance. I think this contributes to a book-like quality. If the cover basis weight is too high, though, the cover may be stiff and hard to open, like a piece of cardboard.

Rule of thumb: A cover basis weight of 80# to 100# is typically conducive to achieving a flat spine and a cover that folds back nicely. Aim for 50# to 60# for the text basis weight.

Tip: To help ensure the cover folds back smoothly, I recommend adding a hinge score. This lightly demarcated fold line, a quarter of an inch from the spine on the front and back covers, not only facilitates the fold but also gives the magazine a nice finished look.

Saddle Stitching

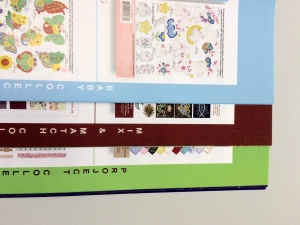

This design was not modified to compensate for creep, so the colored borders get thinner as you move towards the center of the magazine.

Page Count. Just as low page count presents challenges in perfect-bound books, so too can a high page count adversely affect the intended design of saddle-stitched books. As a saddle magazine’s page count grows, live matter that is near the outside edge of the book (opposite the spine) will get closer to the trim on the pages that are closer to the center of the magazine. Printers call this “creep” or “push-out.” Depending on the design elements, some live matter may get trimmed.

Rule of thumb: Avoid formatting live matter closer than half an inch from the trim. Also, talk to your printer if the page count is on the high end (roughly 100-plus pages) and/or the magazine’s specs call for a basis weight of 70# or above. In these scenarios, your printer should work with you to help format interior pages to compensate for creep.

Paper Basis Weight. While perfect-bound magazines benefit from heavier paper stock, saddle stitch books shine on lighter stocks. A saddle-stitch magazine should lie open effortlessly. Pages become stiffer as the text basis weight approaches 70#, and it takes more effort to open the magazine and keep it open.

Rule of thumb: Ideal basis weights for saddle stitch magazines are 45# to 60# for text pages and 70# to 80# for covers.

. . . . .

Join us on Twitter and LinkedIn to share your thoughts & opinions.