By Betsy Robertson

National Account Executive/Lane Press

Recently, I received an urgent email from a university communications director and her colleague (a designer), who’d been asked by their boss to cut a substantial amount of money from the institution’s magazine budget. Unfortunately, their question has become common in a world of competing advancement priorities: How do we reduce publishing costs, yet continue to do right by readers?

Recently, I received an urgent email from a university communications director and her colleague (a designer), who’d been asked by their boss to cut a substantial amount of money from the institution’s magazine budget. Unfortunately, their question has become common in a world of competing advancement priorities: How do we reduce publishing costs, yet continue to do right by readers?

Here are five ideas to trim the budgetary fat.

1. Reduce the number of author’s alterations. Review your print invoices for the past year or two and take stock of the average number of author’s alterations you submit during each issue’s production. When I was an alumni magazine editor, my penchant for perfectionism often led me to make minor text edits at the last minute before we were scheduled to go on press. I was shocked when I began reviewing the costs to fix such problems at the prepress stage: For a 64-page magazine, I was typically submitting corrections on about 15 pages of proofs. At $75 per page, I was adding $1,125 to our quarterly print bill for each issue—or a whopping $4,500 per year in author’s alterations alone.

What I should have done was build an extra two days into the editing schedule for line-proofing and corrections prior to submitting files to the printer. Not only would a more efficient editing process have translated to cheaper production costs, it also would have saved our art director the last-minute aggravation of preparing and resubmitting corrected files. In fact, some of my customers have ceased reviewing hard proofs altogether, decreasing their prepress costs even more.

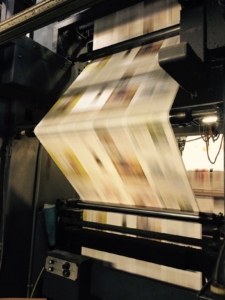

2. Re-examine the magazine’s specifications. Magazine editing and design are creative fields in which stories and layouts are limited largely by the imaginations of writers and designers; printing is essentially a manufacturing operation. That means your printer is working within the boundaries of what its equipment—printing presses, binders, polywrapping lines and other machinery and software—can accomplish. For web printers, the most efficient standard trim size is typically 8.375” x 10.875”. Printers are usually able to manufacture magazines that are smaller or larger than standard, but an unusual trim size may generate more paper waste or incur higher mail costs. Likewise, page counts that are multiples of 16 run more efficiently on web presses than multiples of four or eight. Talk with your print rep about whether your book could be produced more efficiently by making minor changes to the specs—the cost savings may surprise you.

2. Re-examine the magazine’s specifications. Magazine editing and design are creative fields in which stories and layouts are limited largely by the imaginations of writers and designers; printing is essentially a manufacturing operation. That means your printer is working within the boundaries of what its equipment—printing presses, binders, polywrapping lines and other machinery and software—can accomplish. For web printers, the most efficient standard trim size is typically 8.375” x 10.875”. Printers are usually able to manufacture magazines that are smaller or larger than standard, but an unusual trim size may generate more paper waste or incur higher mail costs. Likewise, page counts that are multiples of 16 run more efficiently on web presses than multiples of four or eight. Talk with your print rep about whether your book could be produced more efficiently by making minor changes to the specs—the cost savings may surprise you.

3. Take stock of the paper. How to save money on paper? I lose count of the ways. Paper stock is the single largest raw material in periodical printing and perhaps the most misunderstood. It comes in a wide variety of thicknesses (designated by basis weight), brands, finishes and degrees of brightness. Paper choice is largely influenced by aesthetics — how you want the book to look and feel. You’ll find it much easier to evaluate paper choices if you work closely with your printer to review samples and compare pricing. My advice: Don’t be wedded to a particular brand of paper; your printer may be able to purchase stock from a different mill at a cheaper price that has the exact same basis weight, finish and brightness grade. Also, if environmental sustainability is a factor in your analysis, understand that, in general, the higher the percentage of recycled content, the higher the cost.

4. Limit overruns. If your magazine’s print quantity is higher than 10,000 copies, chances are you’re paying for overruns — books that are printed and finished in excess of the actual print order as part of the manufacturing process. At high print quantities, a printer may agree to limit the number of overruns for which you are invoiced. Calculate your average overs quantity (the actual number of books printed minus the quantity ordered) for several issues and discuss with your printer whether and how the percentage of overruns might be reduced.

5. Consider less expensive mailing options. Periodical mailing methods can be downright confounding. There are three ways to distribute your magazine to readers: origin entry, drop-shipping and co-mailing.

- Origin entry is almost always the most expensive way to mail a periodical. Under this scenario, the printer trucks all your finished books from its plant to the nearest post office and drops them there for the U.S. Postal Service to deliver. Because the USPS does all the work of delivering your book from “origin entry” to your destination addresses, you pay the highest postage rate.

- Under the drop-shipping scenario, your printer delivers books to a facility that sorts and trucks them to regional USPS offices near where most of your individual addresses are located. Because your printer is doing part of the legwork, you receive a substantial postage discount on the mailing; however, you also incur a freight/fuel surcharge. Typically the net total of the surcharge plus the discounted postage rate is still less than what you’d pay under the origin entry scenario, and the delivery window is the same as origin entry at five to 10 days.

- Co-mailing is similar to drop shipping except that books to be co-mailed are added to a “pool” of other publishers’ periodicals that are going to similar locations. All publishers in the pool share in the sortation costs and other expenses associated with mailing, which nets each publication in the pool an even deeper postal discount. Naturally, there’s a fee associated with co-mail in addition to a freight/fuel surcharge, but, again, the net cost will often be cheaper than drop-shipping or origin entry. The primary trade-off with co-mail is that the delivery window is longer at 10 to 14 days rather than five to 10 days.

As an editor faced with mandatory cost cuts, the last thing I wanted to do was eliminate dollars from an already tight freelance budget for writing and artwork. Eliminating fat on the production side can help you look like a hero to your department head—while ensuring your alumni still get the full meal deal from their reading experience.

. . . . .

Join us on Twitter and LinkedIn to share your thoughts & opinions.